We recently shared with you that, for us at Bridgestone, the tyre of the future is connected, resilient, continuous and silent. But that was just part of our vision.

We recently shared with you that, for us at Bridgestone, the tyre of the future is connected, resilient, continuous and silent. But that was just part of our vision. To further help our customers journey into the CASE (Connected, Autonomous, Shared and Electric) mobility era and to address the macro trends, such as climate change and urbanisation, impacting our world and industry, tyres needs to be all these things and more. That’s why the tyre of the future is also:

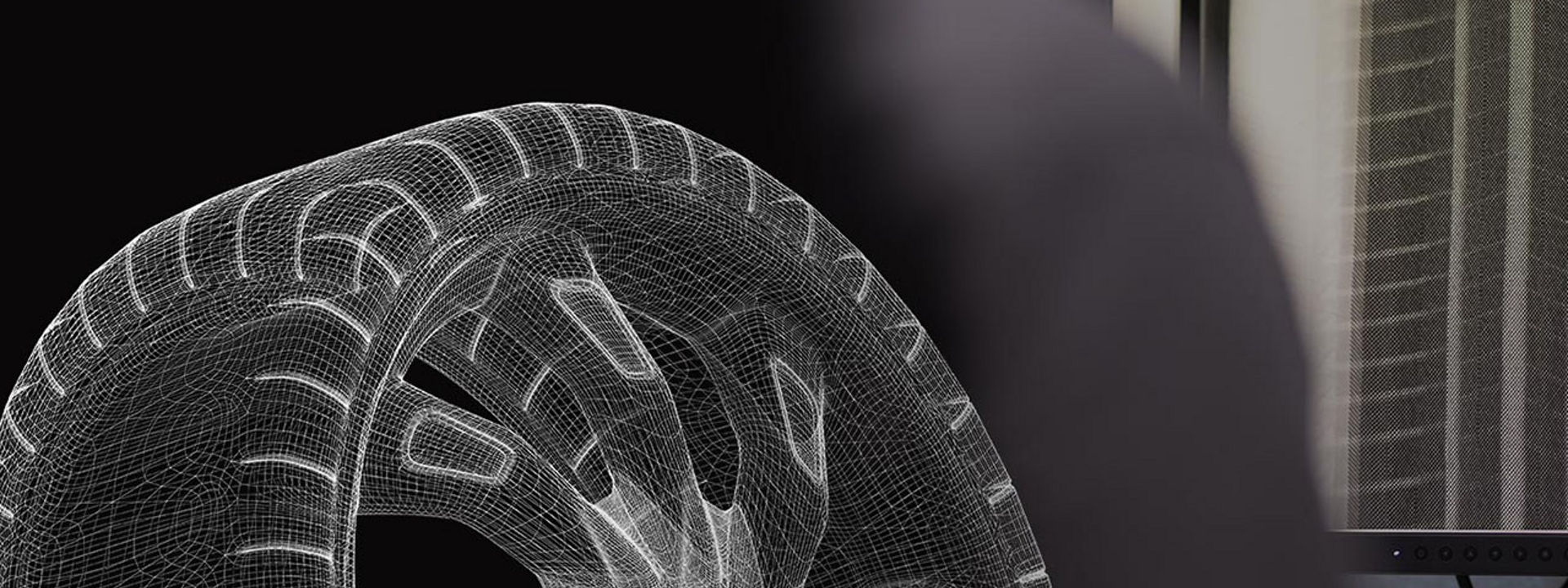

Virtually developed

Traditionally, tyres are developed and fully tested physically. This process requires up to 40,000km of track testing. But now, with Virtual Tyre Modelling, we’re able to offer a solution that complements this process.

Virtual Tyre Modelling enables the creation of a tyre’s digital twin during the development phase. This means that we can digitally examine the tyre’s performance to reduce the number of physical samples needed. Not only does this bring huge environmental benefits, including reduced carbon emissions, but it can also cut the time to market by up to 50 percent.

Through this innovative approach we’re working to achieve the goals around responsible production set by our CSR strategy, ‘Our Way to Serve’. The success of the technology means we’re now looking to integrate it into our testing processes as much as possible.

Energy efficient

At Bridgestone, we’re developing more energy efficient tyres. It’s part of our ongoing work to provide our customers with maximum efficiency and contribute to a more sustainable mobility. Between 2005 and 2018, we managed to reduce the rolling resistance of our entire tyre portfolio by 21 percent, allowing vehicles to cut fuel use and therefore also exhaust emissions. Reduced rolling resistance also has an added advantage for electrical vehicles by saving battery life and increasing the vehicles’ driving range.

At Bridgestone, we developed Ecopia H002, the latest generation of our fuel-efficient Ecopia tyres to address the everyday challenges that long haul fleets face – which includes high fuel costs and increasingly challenging EU CO2 emission regulations. By using our Ecopia H002 tyres on steer, drive, and trailer axles, an average long haul fleet can save more than €200,000 per year on fuel costs and reduce their CO2 emissions by 546 tonnes per year.1

Lighter

We’re also making our tyres lighter to reduce the material resources used in production and improve fuel efficiency when in use. To turn this vision into reality, we developed our lightweight Enliten tyre technology.

The breakthrough technology reduces the weight of passenger tyres by, on average, 10 percent from a standard premium summer touring2 tyre. This means that less raw materials are used in manufacturing, saving valuable resources.

Enliten also reduces the rolling resistance of a passenger tyre by, on average, 20 percent from a standard premium summer touring tyre3. This enables greater fuel efficiency and reduced CO2 emissions in combustion vehicles, while also extending battery life and vehicle range in electric vehicles.

Meeting the demands of new mobility

By taking an innovative approach to tyre design and production, we’re helping to create the next generation of tyres and, in doing so, meet new mobility demands. Our ground-breaking technologies have made virtually developed, lighter, more energy efficient tyres a reality, moving us towards our goal of a more efficient and sustainable future.

1 Financial savings and CO2 reduction versus previous generation Ecopia H001. Difference in fuel consumption and CO2 emission between Ecopia H002 and Ecopia H001 according to Vecto tool for 4x2 tractor and trailer combination .Annual savings projected for an entire fleet based on the following assumptions: fleet size of 150 tractors and 150 trailers, 130,000 km annual mileage per truck, diesel price €1.2/l

2 Based on Bridgestone internal tests according to ISO28580 procedure considering Bridgestone Turanza T005 205/55R16 91H and Bridgestone Turanza T005 255/40R20 101W

3 Based on Bridgestone internal tests according to ISO28580 procedure considering Bridgestone Turanza T005 205/55R16 91H and Bridgestone Turanza T005 255/40R20 101W